Address:

155 Suhong East Road, Suzhou Industrial Park, Jiangsu Province, China

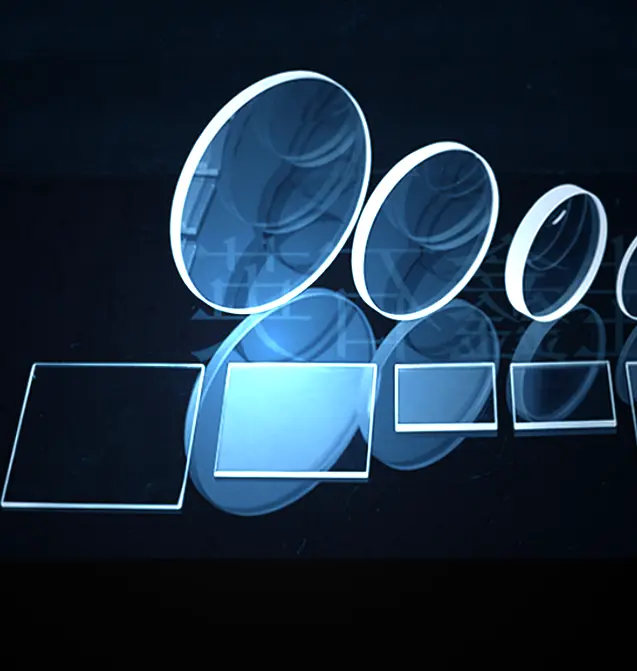

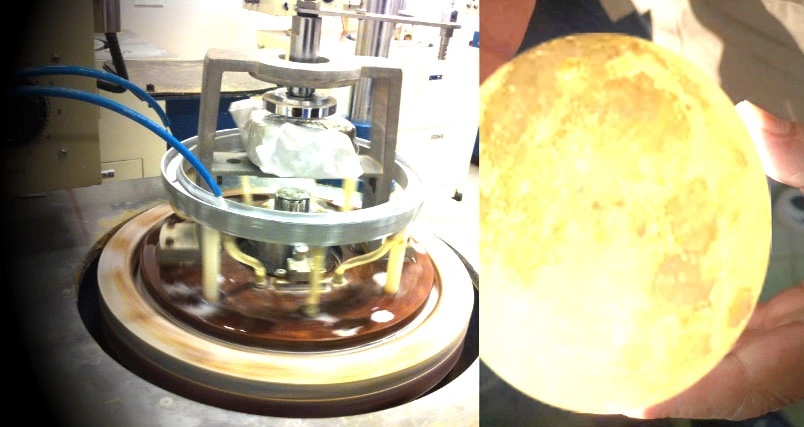

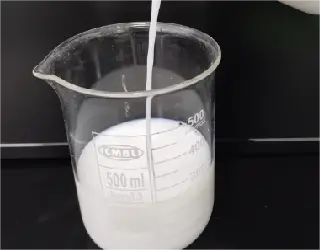

In response to the growing demands of high-performance optoelectronic devices, the Kona team has unveiled a suitable silica colloidal tailored for infrared crystals like lithium niobate and lithium tantalate. This innovative solution promises enhanced efficiency in the challenging polishing process of these soft brittle materials, paving the way for improved manufacturing standards and driving forward the rapidly evolving landscape of optoelectronic technology amidst the rising wave of artificial intelligence.

EN

EN

cn

cn  ja

ja  ko

ko  de

de  es

es  it

it  vi

vi  th

th  ms

ms  id

id